Polyimide

Polyimide is a super engineering plastic that is superior to other materials and has resistance to heat, wear and mechanical abrasion.

Recognized for its excellence, it was selected as the “World’s Best Product.”

About PLAVIS

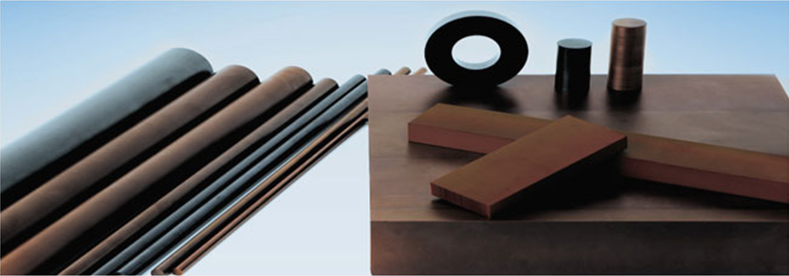

Introduction (POLYIMIDE Molded Parts & Shape)

PLAVIS, the result of our independent polymerization technique, is a wholly aromatic polyimide and exhibits outstanding resistance to heat, wear, mechanical abrasion, radiation and chemicals. Also, due to its ease of manufacture and electrical insulation properties, this environmentally friendly, super engineering plastic is used in various advanced industries including mechanicals, high vibration, electrical/electronics, chemicals, automobiles, space, aviation and military.

Major Characteristics

Grades & Property

available in these four resin compositions to offer a range of property combinations.

| Item | Characteristics | |

|---|---|---|

| Compressive Molding | N/A(N) | Superior mechanical properties, extraordinary resistance to radiation, electricity, heat and chemicals, less gas emission |

| N/A(S) | Super heat-resistant (best mechanical properties at 350° F during continuous operation) | |

| Graphite 15wt% added (G15) | High resistance to wear and tear, extremely low friction factor, suitable for rotating parts of rotary machinery | |

| Graphite 40wt% added (G40) | Greater friction resistance than G15, high dimensional stability | |

| MoS2 15wt% added (MS) | Applicable to vacuum or un-lubricated environment, super wear resistance | |

| Conductive (C) | Electrical conduction, good heat resistance, mechanical properties, surface resistance < 103 | |

| Antistatic (ESD) | Antistatic, good heat resistance and mechanical properties, surface resistance 106 ~ 109 | |

| Non filled (S1)(ESD) | Suitable for test sockets in semiconductor industry with excellent machinability, dimensional stability and laser cleaning stability | |

| Filled (SG) | Suitable for carriers or handling parts in high temperature processes with very high strength and dimensional stability at high temperatures | |

| Non filled (HM) | Suitable for test sockets in semiconductor industry with excellent heat resistance, dimensional stability and high flexural modulus | |

Direct Formed Parts

Direct formed parts are produced using the powder metallurgy process, which involves either compression molding or sintering processes depending on the shapes of parts. Our automatic, advanced manufacturing facilities allow small parts in various grades to be supplied in large quantities.

Machined Parts

Rod- and sheet-type parts are designed for a variety of environments and part shapes. Our machined parts (MP) are manufactured using highly advanced power compressive molding compared to direct formed parts. Due to the resultant absolute accuracy and perfectly even partial density, there are no specific direction properties, which makes PLAVIS machined parts more reliable and extraordinary than direct formed parts.

ROD

| Diameter | Length |

|---|---|

| 1/4” (6.35mm) | 19.6" (500mm) |

| 3/8” (9.53mm) | |

| 7/16” (11.11mm) | |

| 1/2” (12.70mm) | |

| 5/8” (15.88mm) | |

| 3/4" (19.05mm) | |

| 1" (25.40mm) | |

| 1-1/4" (31.75mm) | |

| 1-1/2" (38.10mm) | |

| 2" (50.80mm) |

PLATE

| Length & Width | Thickness |

|---|---|

| 12"×12" (304.8mm×304.8mm) | 12.7~62 (mm) |