Daelim polybutene, the trade name for polybutene made by Daelim Industrial Co. Ltd., is chemically stable and resistant to oxidation by light and heat. All grades are colorless / odorless and not toxic.

It has narrow molecular weight, which leads to outstanding uniformity in quality, and negligible sulfur content.

- Color It is generally waterwhite, less than 50 on the APHA color scale. It remains very stable even when exposed to ultraviolet radiation, and its color is also more stable than that of mineral oil of the same APHA Color.

- ViscosityIt is self-adhesive, and the viscosity increases as molecular weight and viscosity increase.

- Purity and Toxicity It is known for its high purity with extremely low chlorine and sulfur content and non-toxicity by not using additives.

- Stability It shows excellent stability against heat and UV radiation.

- Oxidation stabilityIts excellent oxidation stability leads to good resistance to light and heat during use in ordinary conditions.

- LubricityAs there is no carbon residue at high temperature and it has a high viscosity index, it can be used in blends with other lubricants, oils, etc.

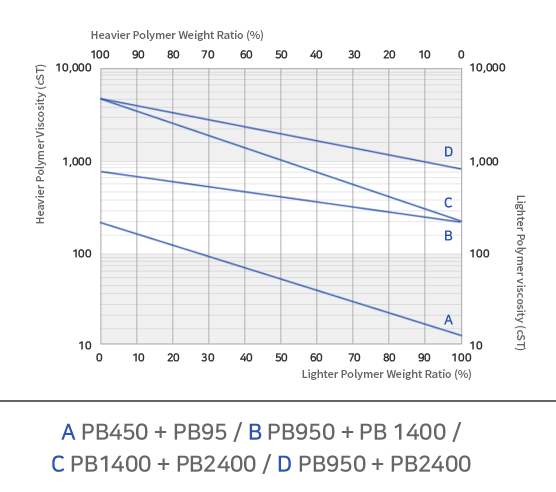

- Viscosity The viscosity varies from 10 to 5000 Cst when measured with a Cannon-Fensky capillary viscometer at 100 ° C. As the molecular weight increases, the viscosity increases.

- - The change in viscosity with varying temperature can be predicted on the basis of ASTM D341 as follows. log log(ν+0.7)=A-BlogT * ν: kinematic viscosity / A,B : Coefficient / Temperature, K

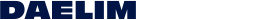

- - When blending Daelim Polybutene with different viscosity, you can obtain products with the desired viscosity. The following formula can be used to roughly calculate the viscosity according to the composition ratio of each grade. Inν= X1Inv1 + X2Inν2-BlogT * ν: kinematic viscosity of the blend / v1: kinematic viscosity of the 1st component / ν2; kinematic viscosity of the 2nd component

X1: weight fraction of the 1st component / X2 : weight fraction of the 2nd component

- - Molecular weight : Its average molecular weight (Mn) ranges from 300 to 2,500, determined by Gel Permeation Chromatography (GPC).

- - The change in viscosity with varying temperature can be predicted on the basis of ASTM D341 as follows. log log(ν+0.7)=A-BlogT * ν: kinematic viscosity / A,B : Coefficient / Temperature, K

- Electrical Properties It does not contain inorganic materials and conductors, and exhibits excellent electrical insulation.

- Chemical Properties It is a non-polar hydrocarbon polymer with high solubility in aliphatic, aromatic, and chlorinated solvents.

Classification, Solvent, PB950 항목 테이블 Classification Solvent PB950 Aliphatic n-Hexane ○ n-Heptane ○ n-Octane ○ Aromatic Benzene ○ Toluene ○ Xylene ○ Ethylbenzene ○ Chlorines Carbon tetrachloride ○ Trichloroethane ○ Methylenechloride ○ Esters Methylacetate Χ Ethylacetate △ Isopropylacetate Χ Alcohols Methanol Χ Ethanol Χ Isopropylalcohol Χ n-Buthanol Χ i-Buthanol Χ ○ Soluble △ Partially soluble Χ Insoluble

Product Performance Table

We supply Con-PB as well as HRPB based on Daelim's own technology protected with patent rights.

| Con-PB (Conventional Polybutene) | |

|---|---|

| Product Characteristics |

|

| Applications |

|

| HRPB (High reactive Polybutene) | |

|---|---|

| Product Characteristics |

|

| Applications |

|

| Classification | 물리적 특징 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Molecular Weight | Viscosity | Flash Point(COC) | Flash Point(PM) | Vinylidene | Color(APHA) | Pour Point | Loss on Heating | Moisture | |

| Unit | Min | cSt @ 100℃ | ℃ | ℃ | Wt-% | Max. | ℃ | Wt-% | Wt-ppm |

| ASTM | GPC | ASTM D445 | ASTM D92 | ASTM D93B | 13C NMR | ASTM D1209 | ASTM D97 | KS-C 2101 | ASTM D6304 |

| PB300 | 330 | 27 (@40℃) | 140 | - | - | 10 | -45 | 0.93 | 20 |

| PB400 | 400 | 10 | - | 130 | - | 10 | -34 | 0.71 | 20 |

| PB680 | 680 | 80 | 175 | - | - | 10 | -13 | 0.14 | 20 |

| PB700M | 775 | 48 | 155 | - | - | 10 | - | - | 20 |

| PB800 | 750 | 100 | 185 | - | - | 10 | -10 | 0.12 | 20 |

| PB950 | 930 | 230 | 205 | - | - | 10 | -9 | 0.1 | 20 |

| PB1300 | 1280 | 640 | 230 | - | - | 10 | 2 | 0.07 | 20 |

| PB1300F | 1280 | 640 | 230 | - | - | 10 | 2 | 0.07 | 20 |

| PB1400 | 1420 | 820 | 235 | - | - | 10 | 5 | 0.07 | 20 |

| PB2000 | 2180 | 2300 | - | 190 | - | 10 | 14 | 0.1 | 20 |

| PB2200M | 2200 | 3260 | 270 | - | - | 10 | 0 | - | 20 |

| PB2350 | 2400 | 4250 | 275 | - | - | 10 | 19 | 0.03 | 20 |

| PB2400 | 2480 | 4740 | 280 | - | - | 10 | 19 | 0.01 | 20 |

| Classification | Chemical Properties | Electrical Properties | Download | ||

|---|---|---|---|---|---|

| Acid Value | Total Sulfur | Dielectric Constant | Dielectric Breakdown Volt | ||

| Unit | mg KOH/g | Max. ppm | - | ㎸ | |

| ASTM | ASTM D664 | ASTM D2785 | ASTM D924 | ASTM D149 | |

| PB300 | 0.005 | 1 | - | - | MSDSpdf icon |

| PB400 | 0.006 | 1 | 2.17 | 40 | MSDSpdf icon |

| PB680 | 0.005 | 1 | 2.18 | 40 | MSDSpdf icon |

| PB700M | 0.006 | 1 | 2.18 | 40 | MSDSpdf icon |

| PB800 | 0.002 | 1 | 2.18 | 40 | MSDSpdf icon |

| PB950 | 0.005 | 1 | 2.18 | 40 | MSDSpdf icon |

| PB1300 | 0.004 | 1 | 2.19 | 50 | MSDSpdf icon |

| PB1300F | 0.004 | 1 | 2.19 | 50 | MSDSpdf icon |

| PB1400 | 0.005 | 1 | 2.19 | 50 | MSDSpdf icon |

| PB2000 | 0.006 | 1 | 2.20 | 50 | MSDSpdf icon |

| PB2200M | 0.004 | 1 | 2.20 | 50 | MSDSpdf icon |

| PB2350 | 0.005 | 1 | 2.20 | 50 | MSDSpdf icon |

| PB2400 | 0.006 | 1 | 2.20 | 50 | MSDSpdf icon |

- Packaging Type

Drum (open/ closed type), Iso-container 항목 테이블 Drum

(open/ closed type)Iso-container 200L (180kg) 24KL (20MT).

| Classification | 물리적 특징 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Molecular Weight | Viscosity | Flash Point(COC) | Flash Point(PM) | Vinylidene | Color(APHA) | Pour Point | Loss on Heating | Moisture | |

| Unit | Min | cSt @ 100℃ | ℃ | ℃ | Wt-% | Max. | ℃ | Wt-% | Wt-ppm |

| ASTM | GPC | ASTM D445 | ASTM D92 | ASTM D93B | 13C NMR | ASTM D1209 | ASTM D97 | KS-C2101 | ASTM D6304 |

| HRPB550 | 590 | 30 | 140 | - | 80 | 10 | - | - | 20 |

| HRPB750 | 770 | 90 | 180 | - | 84 | 10 | - | - | 20 |

| HRPB1000 | 980 | 195 | 230 | - | 86 | 10 | - | - | 20 |

| HRPB1300 | 1300 | 440 | 245 | - | 86 | 10 | - | - | 20 |

| HRPB2300 | 2200 | 1500 | 260 | - | 85 | 10 | - | - | 20 |

| Classification | Chemical Properties | Electrical Properties | Download | |||

|---|---|---|---|---|---|---|

| Acid Value | Total Sulfur | Dielectric Constant | Dielectric Breakdown Volt | |||

| Unit | mg KOH/g | Max. ppm | - | ㎸ | ||

| ASTM | ASTM D664 | ASTM D2785 | ASTM D924 | ASTM D149 | ||

| HRPB550 | 0.007 | - | - | - | MSDSpdf icon | TDSpdf icon |

| HRPB750 | 0.005 | 1 | 2.18 | 40 | MSDSpdf icon | TDSpdf icon |

| HRPB1000 | 0.006 | 1 | 2.18 | 50 | MSDSpdf icon | TDSpdf icon |

| HRPB1300 | 0.005 | 1 | 2.19 | 50 | MSDSpdf icon | TDSpdf icon |

| HRPB2300 | 0.005 | 1 | 2.20 | 50 | MSDSpdf icon | TDSpdf icon |

GRNERAL GRADE @ TYPICAL VALUE

Daelim Polybutene was granted the KT mark for new localized technology and the Ministry of Science & Technology and the Korea Industrial Technology Promotion Association in November 1994. The company also received the IR52 Chang Young-sil Award for Technological excellence in 1995.

| Classification | Physical Properties | Chemical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Molecular Weight |

Viscosity | Flash Point (COC) |

Flash Point (PM) |

Vinylidene | Color (APHA) |

Pour Point |

Loss on Heating |

Water | Acid Value |

||

| Unit | Min | cSt@100℃ | ℃ | ℃ | Wt-% | Pt/Co | Wt-% | Wt-% | Wt-ppm | mgKOH/g | |

| Test Method | GPC | ASTM D445 | ASTM D92 | ASTM D93B | 1H NMR | ASTM D1209 | ASTM D6749 | KS C2101 | ASTM 6304 | ASTM D664 | |

| Conven-tional PB | PB300 | 330 | 27 (@40℃) | 140 | - | - | 10 | -46 | 0.93 | 20 | 0.005 |

| PB400 | 400 | 10 | - | 130 | - | 10 | -34 | 0.71 | 20 | 0.006 | |

| PB680 | 680 | 80 | 175 | - | - | 10 | -13 | 0.14 | 20 | 0.005 | |

| PB700M | 775 | 48 | 155 | - | - | 10 | - | - | 20 | 0.006 | |

| PB800 | 750 | 110 | 185 | - | - | 10 | -10 | 0.12 | 20 | 0.002 | |

| PB950 | 930 | 230 | 205 | - | - | 10 | -9 | 0.1 | 20 | 0.005 | |

| PB1300 | 1280 | 640 | 230 | - | - | 10 | 2 | 0.07 | 20 | 0.004 | |

| PB1300F | 1280 | 640 | 230 | - | - | 10 | 2 | 0.07 | 20 | 0.004 | |

| PB1400 | 1420 | 820 | 235 | - | - | 10 | 5 | 0.07 | 20 | 0.005 | |

| PB2000 | 2180 | 2300 | - | 190 | - | 10 | 14 | 0.1 | 20 | 0.006 | |

| PB2200M | 2200 | 3260 | 270 | - | - | 10 | - | - | 20 | 0.004 | |

| PB2350 | 2400 | 4250 | 275 | - | - | 10 | 19 | 0.03 | 20 | 0.005 | |

| PB2400 | 2480 | 4740 | 280 | - | - | 10 | 19 | 0.01 | 20 | 0.006 | |

| High-Reactive PB | HRPB550 | 590 | 30 | 140 | - | 80 | 10 | - | - | 20 | 0.007 |

| HRPB750 | 770 | 90 | 180 | - | 84 | 10 | - | - | 20 | 0.005 | |

| HRPB1000 | 980 | 195 | 230 | - | 86 | 10 | - | - | 20 | 0.006 | |

| HRPB1300 | 1300 | 440 | 245 | - | 86 | 10 | - | - | 20 | 0.005 | |

| HRPB2300 | 2200 | 1500 | 260 | - | 85 | 10 | - | - | 20 | 0.005 | |

Applications

|

|||

|---|---|---|---|

| FOA | LOA | Lubricant | - |

| GUM BASE | Cosmetics | Electrical Insulation | - |

| HIPS | Tires | Wrap Film | - |

| Fly-Trap | Tape | Hotmale | Adhesive |

- FUEL and LUBRICANT ADDITIVES/LUBRICANTS VThe double bond per molecule allows the production of fuel detergent, lubricant dispersant, etc. through chemical reaction.

- Fuel detergent additive reduces deposits on engine valves, fuel injectors, pistons, carburetors and combustion chambers, and decreases exhaust emissions, prolonging the lifetime of the engine.

- Lubricant dispersants minimize engine deposits formed due to a lack of engine priming from sudden acceleration. Those in commercial use are prepared using polybutene.

- LUBRICANTS

- Two-Stroke Engine OilTwo-stroke engines are used in scooters, lawn mowers, chainsaws and boats. Adding Daelim Polybutene reduces smoke in the engine exhaust system at high temperature.

- Lubricant for Rolling and Wire DrawingUnlike mineral oil, Daelim Polybutene leaves almost no carbon residue in rolling operation and wire drawing involving aluminum and copper. It is environmentally friendly, helping to solve pollution problems.

- Compressor OilDaelim Polybutene is free of sulfur and other impurities, which removes the danger of catalytic poison and other problems.

- Viscosity Index ImproversA viscosity index improver with Daelim Polybutene added minimizes changes in lubricant oil viscosity affected by temperature.

- ADHESIVESDaelim Polybutene is used for wide applications in the formulation of various types of adhesives.

- Pressure Sensitive Adhesive(PSA) Raw material

- - Base polymer : natural rubber, SIS, SBR, PIB, etc.

- - Adhesives : hydrocarbon resin, rosin, polybutene, etc.

- - Others : filler, antioxidant, solvent, etc.

- - Polybutene improves the tack and peel strength of elastomers. The major applications of PSA are general and insulation tapes.

- Hot Melt Adhesive(HMA)Raw material

- - Base polymer : EVA, SBS, SIS, APP, PE, etc.

- - Adhesives : hydrocarbon resin, polybutene, etc.

- - Others : paraffin wax, filler, antioxidant, etc.

- Daelim Polybutene increases the melt index (MI) and provides flexibility at low temperatures. It is very compatible with SBS, SEBS, SIS, and PE. The major applications of HMA include packaging, book binding, and disposables such as diapers.

- Pressure Sensitive Adhesive(PSA) Raw material

- CAULK and SEALANTDaelim Polybutene is used for caulk and sealants as a Adhesives and plasticizer with excellent non-drying UV stability and viscosity. The main uses of caulk and sealants with Daelim Polybutene are for construction, automobiles, shipbuilding and refrigerators.

Daelim Polybutene meets the standards regulation designated by the Korea Food Additives Board, and it is currently used as a base material for chewing gum and bubblegum.

| Item | PB1300F | PB1400F | PB1500F | |

|---|---|---|---|---|

| Viscosity (cSt 100℃) | 645 | 810 | 4700 | |

| Properties | Pass | Pass | Pass | |

| Verification Test | IR Spectrum | Pass | Pass | Pass |

| Bromine Reagent | Pass | Pass | Pass | |

| Heat Test | Pass | Pass | Pass | |

| - | Solubility | Pass | Pass | Pass |

| Chlorine Compound | Pass | Pass | Pass | |

| Arsenic | Pass | Pass | Pass | |

| Heavy Metal | Pass | Pass | Pass | |

| Low Polymer Contents | Pass | Pass | Pass | |

| High Heat Residue | Pass | Pass | Pass | |

Adding 1~6% Polybutene to LLDPE improves film properties including elongation, tear resistance, impact strength, viscosity and low temperature flexibility. Its main applications include industrial stretch film and wrap film.

Daelim Polybutene is mainly used in electrical applications, such as jelly compound due to excellent electrical properties from a lack impurities.

- Cable Jelly CompoundIts great heat stability, waterproofing property and low power factor is appropriate for use as a petroleum jelly compound.

- Insulation Oil for CondensersIt is used as insulation oil for low voltage condensers because of its outstanding electrical properties, heat stability and oxidation stability.

- Asphalt ModifierEnhances low temperature flexibility, waterproof property, and viscosity when used in asphalt sheet.

- Resin PlasticizerIncreases melt index and strength when added to olefinic and styrenic resin.

- Rubber ModifierImproves viscosity and flexibility at low temperature when added to rubber.

- Dispersing AgentA useful dispersing agent for pigment and ink. Also, it is used as the assistant material of the foaming agent of synthetic resin including PS, PE and PP.

Application technical note

| ATN-Additives | |

|---|---|

| ATN-Electrical insulation |

|

| ATN-Other applications |

|

| ATN-Sealant | |

| ATN-Adhesive | |

| ATN-Lubricant | |

| ATN-Polymer modifier |

Contact information

-

Team Leader Youngbin Park (domestic demand )

02-3708-3560 / jerrypark@daelimcorp.co.kr